High Chrome Casting Quarry Impact Crusher Wear Parts Stone Crusher Blow Bar

Basic Info

| Surface Treatment | Polishing |

| Manufacturing Process | Casting |

| Transport Package | Standard Export Package |

| Specification | 1300*650*300mm |

| Trademark | hyton |

| Origin | China |

| HS Code | 84749000 |

| Production Capacity | 500000PCS/Year |

Product Description

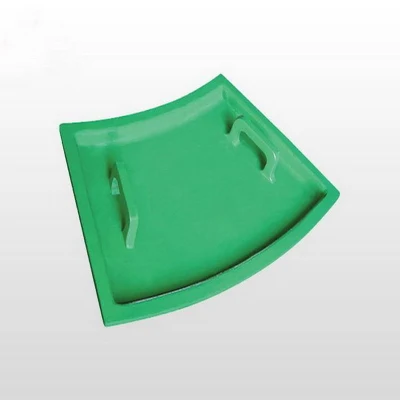

High Chrome Casting Quarry Impact Crusher Wear Parts Stone Crusher Blow Bar

Products Description

Hyton is a famous foundry of high manganese and high chrome castings for more than 16 years. Our main products are mantle,concave,jaw plate, blow bar,hammers and vsi crusher wear parts etc. About impact crusher and hammer crusher parts, hyton focus on being help on blow bar, breaker plate, hammers.

| Product Name | Blow Bar |

| Application Crusher | Impact Crusher |

| Material | High Manganese Steel,High chrome,Medium chrome, lower chrome |

| Production Test | Hardness testing, metallographic testing, spectral analysis, mechanical properties and heat treatment. |

| Life Time | 100% match original OEM quality |

| Production Type | Casting |

| Surface Treatment | Polishing |

| Certificate | ISO9001 |

Products PicturesMaterial Composition

High Manganese Steel Blow Bar: Mn18Cr2

| C | Si | Mn | P | S | Cr |

| 1.20-1.35 | Max1.0 | 16-19 | Max0.07 | Max0.07 | 1.5-2.5 |

Chrome Alloy Steel Blow Bar:High chrome,Medium chrome, lower chrome

| Cr | C | Na | Cu | Mn | Si | P |

| 3.5-4.5 | 2.5-3.5 | / | / | 0.5-1.0 | 0.5-1.0 | ≤0.15 |

| 8.0-1.0 | 2.5-3.6 | 4.5-6.5 | 4.5-6.5 | 0.3-0.8 | 1.5-2.2 | / |

| 13-18 | 2.8-3.5 | 0-1.0 | 0-1.0 | 0.5-1.0 | ≤1.0 | ≤0.16 |

| 18-23 | 2.0-3.3 | ≤2.5 | ≤1.2 | ≤2.0 | ≤1.2 | ≤0.16 |

| 23-30 | 2.3-3.3 | ≤2.5 | ≤2.0 | ≤1.0 | ≤1.2 | ≤0.16 |

Main Models We Supply:

NP1213,NP1313,NP1415,NP1620,NP1520,NP1110,NP13,NP15,LT1213,LT1315CI121,CI123,CI124,CI125,CI221,CI231,CI222,CI232,CI223,CI233,CI224,CI234,CI225,CI235I-100,I-100RS,I-120,I-120RS,I-140,I-140RSHS-2421,HS-2430,HS-3036,HS-3048,HS-4230,HS-5252,HS-5263APP4354,APP5148,APP5560,APP6384,APP8084,APS4034,APS4054,APS5148,APS5160,APS6084

Note: other model we can produce according to customer's drawings.

Production Scene

Inspection Reports We will provide inspection reports for your confirmation before shipment if necessary.

Company Profile

Hyton(Jiangsu) Mechnical Equipment Co.ltd is a leading enterprise in the large-scale engineering machinery wear-resisting casting industry in Jiangsu Province,Nantong City. As a new high-tech enterprise professionally manufacturing wear-resisting casting product Which specialized in manufacturing and research of High manganese and high Chrome wear parts. After ten years of rapid development, Hyton(Jiangsu) has now become a renowned enterprise in China's wear-resisting casting industry; it has become one of the famous supplier of wear parts for crusher and concrete mixer .Established in June 2004, the company is now undertaking a National Torch Program Project, and five of its patented products have been honored as the "New High-Tech Product" of Jiangsu Province two of which have been listed into the New Products Program of Jiangsu Province.The company's wear-resisting casting products have been praised to be the "Famous-brand Products of Jiangsu Province", the company has been appraised as a "Trustworthy" unit of Jiangsu Province for many consecutive years.

Located in the New Material Industrial Park, Nantong City Jiangsu Province. the company covers an area of 90 Square kilometer and currently has more than 300 employees. The company is equipped with lost molding production line and lost casting production line imported from FATA Company in Italy, Inductotherm Vacuum Degassing Furnace(USA), Foseco Casting Technology(U.K), SPECTRO Spectrometer (Germany), the currently most advanced ZZ418A vertical parting flaskless shoot squeeze molding machine Disa production line, horizontal molding line and self-control lost casting production line in China,the most advanced sand treatment system in China,. With three gas trolley heat treatment furnace and pusher-type furnace full-automatic heat treatment production lines, the company can annually produce 30,000 tons of various wear-resisting castings.Related ProductsPackage and Shipment

FAQ

1.

Q: Are you trading company or manufacturer?

A: We are a foundry, has been specializing in this industry for more than 16 years. We equip with complete facilities, all production process from manufacturing to testing is finished in our own foundry.

2.

Q: How long is your delivery time?

A:Our lead time is generally 30 days for existing patterns, 55 days for new patterns. Exact time to be finalized on receiving of finalized order.

3.

Q:What kind of products do you make?

A: We specialize in mining machinery parts, such as jaw plates, concaves, mantles, bowl liners, , shredder hammers, blow bar,breaker plate and other customized castings.

4.

Q:Do you offer the supporting service for technology and engineering?

A: Yes. our engineering team can measure products at mining site, they also can make more reasonable design for the crusher parts.

5.

Q:How do you deal with quality problem?

A: we adhere to "Be honest people create perfect product" development principle since our foundation.Every single product is strictly checked and well packed before delivery. If something goes wrong when you use our products,please send us photos of the wear part and the machine. This will help us to identify where the problem is. If it is a quality problem, we will compensate you and do something correspondingly to avoid the same problem next time. If the problem is caused by misuse,we will provide our technical advice for your reference.

6.

Q: what is the best route to come to visting your plant?

A: Shanghai to Nantong station around one hour by high speed train. we will pick you up at the high speed train station